What Are Smart Materials Innovations for the Future

Explore smart materials—innovative substances that react to heat, light, and stress—and their game-changing role in the future of technology and design.

Smart materials, also known as intelligent or responsive materials, are advanced substances that can change their properties in response to external stimuli such as temperature, pressure, and electric or magnetic fields.[1][2] This unique capability enables smart materials to offer innovative solutions across diverse sectors, including aerospace, construction, and healthcare. As industries increasingly adopt these materials, their potential to enhance performance, safety, and efficiency is being recognized, making them a focal point of modern materials science and engineer- ing.[3][4]

One of the most notable applications of smart materials is in the aerospace industry, where companies like Boeing and Airbus are integrating these technologies to improve aircraft design and functionality. Innovations such as piezoelectric sensors and shape memory alloys contribute to weight reduction, enhanced fuel efficiency, and the reduction of noise and vibrations.[5][6] Additionally, smart materials like thermoelectric materials are being utilized for energy harvesting and temperature regulation, showcasing their broad utility within the field.[6][2]

In construction, smart materials such as smart concrete have revolutionized struc- tural monitoring and safety. By embedding carbon fibers within concrete, this ma- terial can detect structural flaws and adapt its properties, thus contributing to the development of smart cities and improving infrastructure resilience.[7] Despite their promising applications, the integration of smart materials faces challenges related to cost, skilled labor shortages, and management support, hindering their widespread adoption.[8][9]

The future of smart materials appears bright, with ongoing research focusing on enhancing their functionalities while addressing environmental concerns. Emerging technologies, such as artificial intelligence, are poised to play a critical role in ad- vancing smart materials by facilitating material discovery and promoting sustainable practices. As the field continues to evolve, the transformative potential of smart materials across various sectors is expected to grow, driving innovations that redefine traditional design and functionality paradigms.[10][11][12]

Types of Smart Materials

Smart materials can be classified into several categories based on their properties and responses to external stimuli. Each type exhibits unique characteristics that make them suitable for various applications across multiple industries.

Piezoelectric Materials

Piezoelectric materials generate an electric charge in response to applied mechan- ical stress and can change shape when an electric field is applied. They are widely used in sensors, actuators, and energy harvesting technologies due to their compact size and high response rates[1][3].

Magnetostrictive Materials

These materials change shape or dimensions when exposed to a magnetic field, enabling their use in sensors and actuators. An example of a magnetostrictive material is Terfenol-D, which is valued for its high energy density and efficiency in converting magnetic energy into mechanical work[4][5].

Self-Healing Materials

Self-healing materials possess the intrinsic ability to repair damage autonomous- ly, significantly enhancing their lifespan. These materials can be categorized into endogenous, which utilize the material's properties for self-repair, and exogenous, which rely on stored repair agents that are activated when needed[6][3].

Smart Polymers

Smart polymers are capable of undergoing reversible changes in their physical or chemical properties in response to specific stimuli. These materials can react to changes in temperature, pH, or other environmental factors, making them valuable in applications such as drug delivery systems and responsive coatings[13][1].

Smart Alloys

Smart alloys, such as shape memory alloys (SMAs), are designed to change their shape or mechanical properties in response to variations in temperature or stress. SMAs can return to their original shape after deformation, which is particularly useful in applications like self-healing structures and actuators[13][4].

Smart Fluids

Smart fluids can alter their viscosity and other properties in response to external fields, such as magnetic or electric fields. An example of this is magnetorheological materials, which change their flow characteristics when subjected to a magnetic field, allowing for applications in shock absorbers and vibration dampers[1][5].

Chromogenic Materials

![]() Chromogenic systems change color in response to electrical, optical, or thermal stim- uli. This category includes electrochromic materials, which alter their opacity when a voltage is applied, thermochromic materials that change color with temperature vari- ations, and photochromic materials that respond to light exposure. These materials have applications in smart windows, automotive mirrors, and displays[14][5].

Chromogenic systems change color in response to electrical, optical, or thermal stim- uli. This category includes electrochromic materials, which alter their opacity when a voltage is applied, thermochromic materials that change color with temperature vari- ations, and photochromic materials that respond to light exposure. These materials have applications in smart windows, automotive mirrors, and displays[14][5].

Dielectric Elastomers

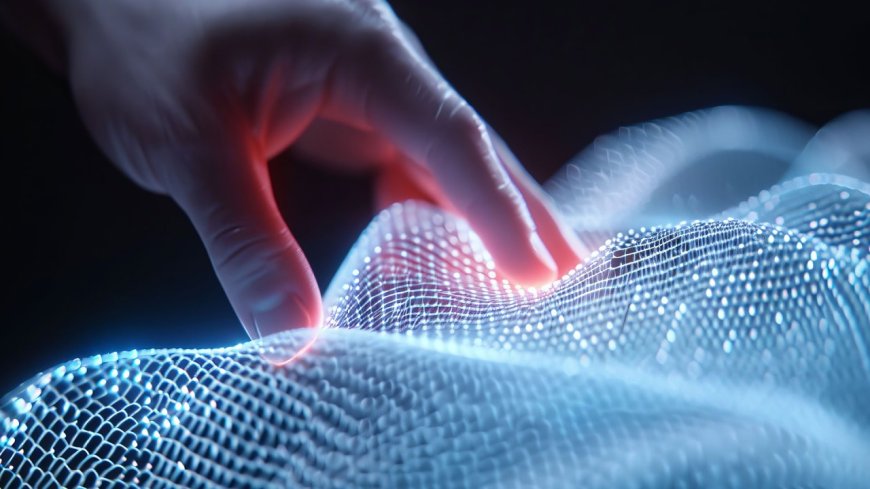

![]() Dielectric elastomers are a type of electroactive polymer that can undergo large strains (up to 500%) when subjected to an electric field. This property allows them to function effectively in applications such as soft robotics and artificial muscles[13][14].

Dielectric elastomers are a type of electroactive polymer that can undergo large strains (up to 500%) when subjected to an electric field. This property allows them to function effectively in applications such as soft robotics and artificial muscles[13][14].

Innovations in Smart Materials

Overview of Smart Materials

Smart materials, also referred to as intelligent or responsive materials, exhibit unique capabilities that allow them to alter their properties in response to external stimuli such as temperature, pressure, electric and magnetic fields, and moisture[2][6].

This responsiveness enables the development of innovative solutions across var- ious industries, including aerospace, construction, and consumer electronics. The aerospace sector, in particular, leverages smart materials to meet the growing demands of air travel, as the number of air passengers is projected to double by 2036[2].

Aerospace Applications

In the aerospace industry, smart materials play a crucial role in enhancing perfor- mance and safety while reducing costs. Companies like Boeing and Airbus are at the forefront of integrating smart materials into their designs. For instance, Boeing employs smart material-actuated rotor technology that can reduce noise and improve flight performance by minimizing vibrations by approximately 80%[2]. Additionally, piezoelectric sensors are utilized in Boeing 777 aircraft to monitor ultrasonic levels in fuel tanks, showcasing the practical benefits of these advanced materials[2].

Shape Memory Alloys

Shape memory alloys (SMAs) represent one of the most significant advancements in smart materials for aerospace applications. These materials can return to a pre- determined shape when exposed to specific stimuli, allowing for innovative designs and functionalities. The use of advanced composites, such as carbon fiber-reinforced polymer (CFRP), further enhances the structural integrity of aircraft while contributing to significant weight reductions and improved fuel efficiency[2][13].

Thermoelectric Materials

Thermoelectric materials are another area of innovation within the realm of smart materials. These materials can efficiently convert temperature differences into elec- trical energy, facilitating temperature regulation and energy harvesting in aerospace applications[6]. Their integration into aircraft can lead to improved energy efficiency and operational sustainability.

Construction Innovations

The construction industry is also experiencing a paradigm shift with the incorporation of smart materials. Innovations such as smart concrete, which is embedded with carbon fibers, have the capacity to detect structural flaws and enhance strength compared to traditional concrete[7]. This adaptability not only improves safety but also supports the smart city concept by providing real-time monitoring capabilities for infrastructure.

Smart Concrete

Smart concrete can change its electrical conductivity in response to loading and unloading processes, making it an effective tool for structural health monitoring and traffic management systems[7]. Additionally, it has potential applications in snow melting on roads, where electrical currents can be used to prevent ice buildup.

Future Potential

The future of smart materials is promising, with ongoing research aimed at over- coming current challenges related to cost, durability, and environmental impact[8]. As these materials continue to evolve, their ability to adapt and respond to environ- mental changes will drive advancements in multiple sectors, transforming design and functionality in ways previously unimaginable.

Challenges and Limitations

Management Support and Integration

The successful implementation of smart materials innovations hinges significantly on management support and the integration of various departments within an organiza- tion. As companies aim to embrace advancements such as Industry 4.0, obtaining cooperation across all levels can be particularly challenging, especially when dealing with new technological developments. This integration is crucial to overcome the inertia that often accompanies shifts towards innovative practices[9][10].

Cost Implications

One of the predominant barriers to adopting smart materials is the high cost asso- ciated with advanced technologies such as robotics, artificial intelligence (AI), and augmented reality (AR). This challenge is exacerbated for small and medium-sized

Skills and Knowledge Gap

The lack of understanding regarding Industry 4.0 among employees poses a signif- icant challenge. Organizations often face difficulties in finding skilled personnel who are familiar with these advanced technologies. This skills gap not only impedes the adoption process but also affects the ability to effectively implement smart materials innovations, as the workforce may not possess the requisite knowledge to operate or integrate these new systems effectively[10][15].

Environmental Context and Network Externalities

Companies also face environmental challenges, such as network externalities. For instance, organizations may be reluctant to share production methods or proprietary information, which can hinder collaboration and the overall adoption of smart ma- terials innovations. This desire to maintain confidentiality can prevent companies from leveraging the benefits that come from shared knowledge and technology networks[15].

Data Management Challenges

Data interoperability and management are significant obstacles in the integration of smart materials into existing manufacturing processes. Issues such as data compat- ibility, security, and the lack of effective data management systems have been iden- tified as primary barriers to adopting Industry 4.0 technologies. Many organizations struggle with the complexities of data collection, storage, and analysis, which are critical for ensuring effective decision-making and operational efficiency[10][15].

Cultural and Organizational Barriers

Cultural challenges within organizations can also impede the adoption of smart materials. Resistance to change from management or employees can stem from a lack of support for innovative initiatives or fear of job displacement. Moreover, the organizational structure may not be conducive to rapid adaptation required for the implementation of new technologies[15].

These challenges highlight the multifaceted nature of adopting smart materials innovations, underscoring the necessity for organizations to address management, financial, skill-related, environmental, and cultural factors to facilitate successful implementation.

Future Prospects

As the field of materials science continues to evolve, the future of smart materials appears promising, with innovative applications poised to revolutionize numerous sectors. The year 2023 has marked a pivotal point in the advancement of smart ma- terials, with ongoing research indicating a trajectory toward even more sophisticated capabilities and functionalities[11][12].

Technological Integration

The integration of smart materials with emerging technologies such as artificial intelligence (AI) and advanced manufacturing processes is set to enhance their effectiveness and applicability. For instance, AI is playing a crucial role in accelerating the discovery and development of new materials. By leveraging large datasets, AI algorithms can identify promising material properties, conduct predictive modeling, and even create new materials autonomously[16][17]. This technological synergy will facilitate more efficient material synthesis, reduce waste, and promote sustainable practices across industries[12][16].

Diverse Applications

The potential applications for smart materials are extensive and varied. From health- care to aerospace, these materials are expected to bring transformative benefits.

In healthcare, smart materials could lead to innovations in patient care, such as self-healing medical devices and responsive implants that adapt to physiological changes[12]. In the construction industry, smart materials may enhance building efficiency and durability, enabling structures that can respond dynamically to envi- ronmental stimuli[7].

Sustainability and Environmental Stewardship

A key focus for the future will be the development of sustainable smart materials that contribute to environmental stewardship. Researchers are investigating materials that not only perform well but also minimize ecological impact, aligning with global efforts towards sustainability[11]. The future landscape of smart materials is likely to emphasize the importance of reducing carbon footprints and utilizing renewable resources in their production and application.

Challenges Ahead

Despite the exciting prospects, challenges remain, particularly in the realms of workforce skills and adoption of new technologies. The current labor shortage in manufacturing highlights the need for a skilled workforce capable of leveraging advanced technologies, including smart materials[18]. Addressing these workforce challenges through education and training will be crucial to maximizing the benefits of smart materials in future applications.

References

[1] : Work smarter, not harder: what are smart materials?

[2] : Development and Prospect of Smart Materials and Structures for ... - MDPI

[3] : Smart Materials: Innovation & Applications | Vaia

[4] : New and Emerging Smart Materials and Their Applications: A Review

[5] : Smart Materials- Types & Applications - IJRASET

[6] : Smart Materials: Examples, Types, applications – FAQs

[7] : Smart material - Wikipedia

[8] : Cutting-Edge Advancements in Smart Materials for Aerospace - AZoM.com

[9] : Smart Materials in Construction: Opportunities and Challenges - AZoBuild [10]: Smart Materials in Design — Simples Agency

[11] : Integrating industry 4.0 in manufacturing: overcoming challenges and ...

[12] : Smart Materials in Aviation: Transforming Aircraft Design and ...

[13] : Innovative Smart Materials Transforming Automotive Design

[14] : Innovative Materials Spotlighted in 2023 | Blog | CUUB Studio

[15] : The Future of Smart Materials Applications in Health and Technology

[16] : Digital Transformation in the Materials Industry | StartUs Insights

[17] : Latest Trends in Smart Material Technology | Restackio